This page serves as a Troubleshooting Guide for the NTK – NGK Powerdex AFX & Ballenger Motorsports AFR500 & AFR500v2 Wideband O2 Air Fuel Ratio Monitor Kit.

NGK Powerdex AFX & Ballenger Motorsports AFR500 Error Codes

The most common error code is SEN6, which indicates a problem with the sensor and/or wiring to the sensor. Listed below are all the error codes available for the NGK Powerdex AFX & Ballenger Motorsports AFR500 & AFR500v2

| Error code | Description |

| 1 ——-> | Heater open (wire open or sensing element cracked) or no sensor connected |

| 2 ——-> | Heater shorted (wiring problem, H+ wire connected to GND) |

| 3 ——-> | Supply voltage out of range (28V) |

| 4 ——-> | Vs voltage > 1.7V (sensor too cold/not ready for measurement or Vs+ electrode cracked or Vs+ wire open) |

| 5 ——-> | (not used) |

| 6 ——-> | Ip+ voltage out of range ( sensing element cracked or IP+ wire open ) |

Top causes for an Error:

- Bad Sensor due to rich misfiring (tuning far too rich and/or raw fuel hitting the sensor possibly leading to a cracked ceramic or contaminated ceramic element).

- Bad Sensor due to having the sensor in the exhaust stream with no control and no heating which almost immediately foul a sensor.

- Bad Sensor due to bad manufacturing or damage in transit or improper installation (sensor is at the bottom of the pipe, etc).

- Sensor not reading within range due to being too hot or cold (ie right next to the port or way down the exhaust stream).

- Wiring in harness is loose, pull each wire individually on each connector to validate fully seated terminals.

- Wiring is improperly populated (crossed), send customer images and make sure to tell them to validate direction using keyways.

- Bad ground connection to the controller or bad power connection. The voltage should be a DC supply voltage between 11 and 28 volts. If the voltage drops below 11 it will reset itself (sometimes this happens during cranking). We have seen bad wiring contribute to sensor problems often. Try connecting your power and ground directly to a good battery and see if your issue remains.

Remember this!:

The number one most important thing to remember for all tuners but especially novice tuners is that misfire events read as FULL LEAN! This occurs because this sensor is an OXYGEN sensor and when a misfire event occurs, the sensor will read pure oxygen and report a reading equivalent to free air. Being an oxygen sensor, it has no way to determine that fuel is in the exhaust as well so this determination is up to the tuner. Please pay attention to your other sensors such as smell, sight, sound and simple methods such as plug reading. A car that is misfiring will have an audible difference just as a car that is too rich will smell differently and a too rich exhaust may pour out black smoke. Running far too rich with frequent misfires and/or backfires can ruin a sensor quickly.

The number two most important thing to remember is to install the sensor in the proper location and never have it installed in the pipe without the controller connected and powered up. Having a sensor installed pointing directly down to the ground or having it in the pipe with no control can lead to very rapid failure.

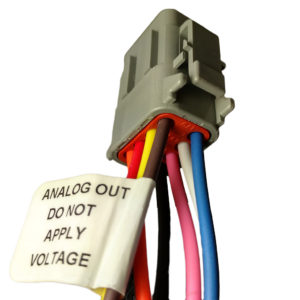

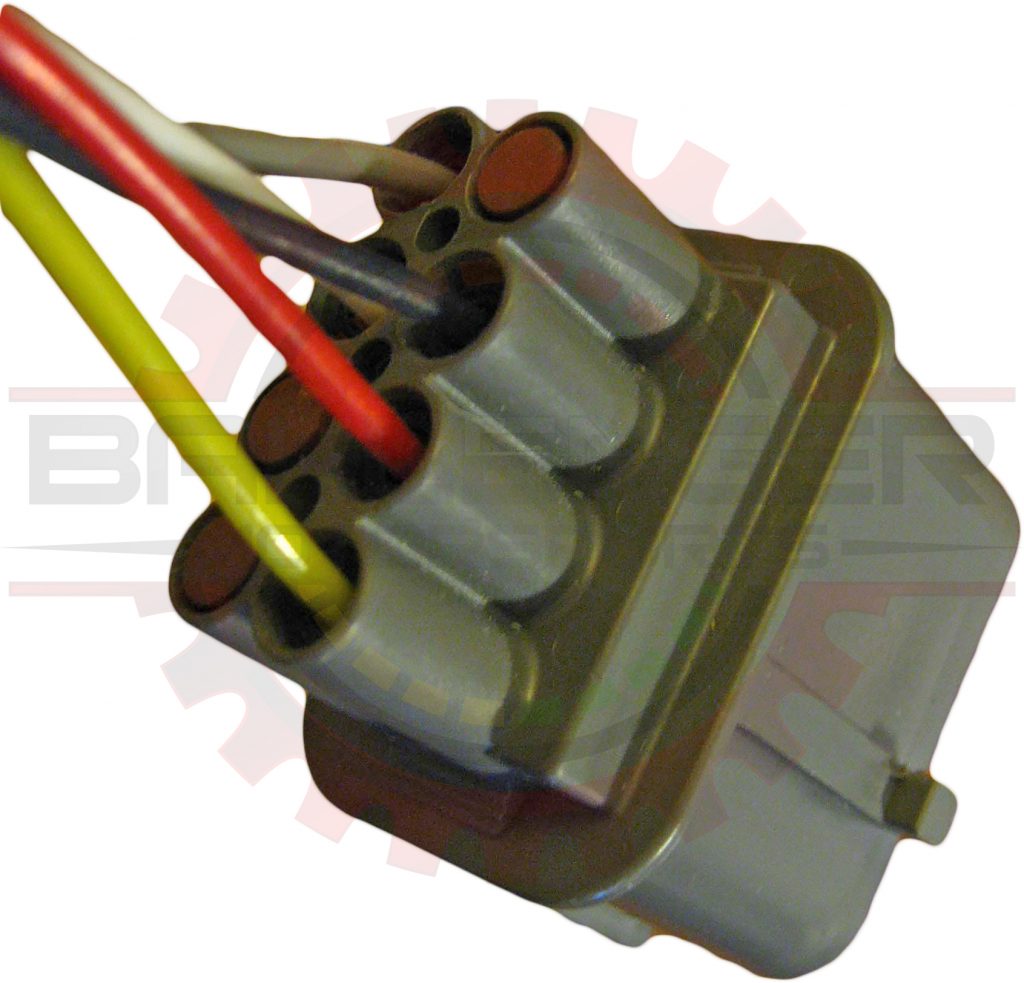

Images of Connectors for Pinout Validation:

Pay Careful Attention to the keyway patterns to ensure you are comparing the pinouts with the proper orientation.

Bosch LSU Sensor for AFX/AFR500/AFR500v2 – Pinout (image 1 of 1)